The Important Function Of Hydraulic Pumps In Excavator Function

페이지 정보

본문

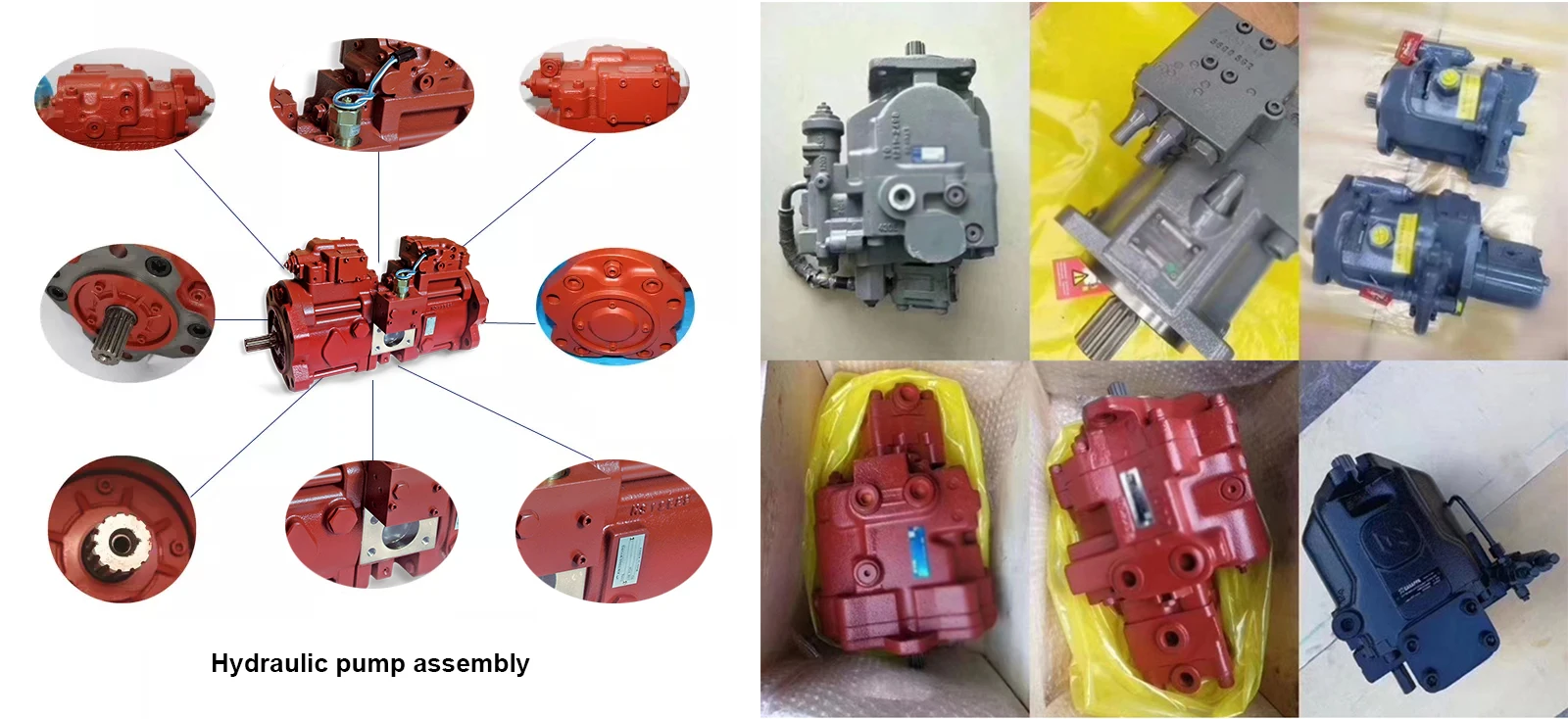

Excavators are versatile heavy building tools that use hydraulic power to dig, carry, and transfer materials efficiently. The hydraulic pump for excavator is the center of an excavator’s K3V hydraulic pump system, supplying the stream and strain wanted to power the hydraulics for work capabilities. Selecting the best hydraulic pump is essential for optimal excavator efficiency and productiveness. This second is made attainable by an eight.3-liter displacement diesel engine that may generate as much as 350 horsepower. This engine drives a pair of pumps with up to one hundred fifty gallons per minute circulate fee delivered at a pressure of 4,500 psi. The pumps hydraulic pistons have 5.5-inch diameter faces and 4-inch diameter shafts.

Once you encounter problems with bobcat excavator hydraulics it is essential to repair them instantly. For those who delay too much, extra injury can happen and tools could also be misplaced. In case you don’t have enough data and required tools, find somebody who can do it for you with none difficulties. Learn our article about learn how to determine and diagnose bobcat excavator hydraulic issues in order that you'll be taught extra about why they could occur in the first place while ready. Development Equipment Elements is your go-to destination for quality excavator elements. Whether or not you function John Deere, Caterpillar, Volvo, Komatsu, Hitachi, Hyundai, or Link-Belt excavators, Development Equipment Components affords an answer to meet your machine's needs. Our choice consists of a wide range of essential elements resembling alternators, arms, attachments, booms, bucket hyperlinks, buckets, bushings, cabs, computers, dippers, engine control models (ECUs), transmission management items (TCUs), engine rebuild kits, and radiators.

Three. Do not use hydraulic breaker to move rocks with finish of instrument or with hydraulic breaker body. Four. Don't use device as a lever. Hydraulic breaker could possibly be damaged at by means of bolt,software, front head internal bush and entrance cover. 5. Move affect point of object, if the article does not break with in 30 seconds. Minor galling is expected, but when deep scarring becomes noticeable, it's good to substitute the retaining pins. In the event you choose to not, the pins may deform, making them very tough to remove. "When replacing tool retainers, at all times change them in sets and rotate them equally," says Miller. The working steel must be inspected weekly.

Consulting with the producer or a specialist can assist you choose the best suited attachment. How do I maintain an excavator dredge pump attachment? Regular upkeep consists of checking and cleansing the pump, inspecting hoses and connections for wear and tear, and making certain the hydraulic system is in good situation. Observe the manufacturer’s guidelines for specific maintenance procedures. Can the attachment be utilized in saltwater environments? Many excavator dredge pump attachments are designed to function in freshwater and saltwater environments. Nonetheless, it's important to choose a mannequin with corrosion-resistant materials and coatings.

Whether you want a compact mini excavator or a heavy-responsibility crawler, now we have the solution. Gregory Poole is your trusted accomplice in buying and sustaining Cat excavators. Our specialists are prepared to help you in selecting the suitable tools to your wants and supply high-notch service and help throughout your ownership. Explore our range of tools right this moment and elevate your construction and excavation projects with the perfect within the trade. Reach out in case you have any questions. If not properly filtered out, the contaminants construct up and lead to a system failure. Changing the hydraulic fluid filter frequently is a key practice in how to take care of a hydraulic system. What Are the principle Maintenance Needs of a Hydraulic System? Hydraulic programs in earthmoving gear have particular and common maintenance needs that each one house owners ought to be aware of. Their strong construction can withstand the rigors of powerful working circumstances, making certain durability and lengthy-time period service. Moreover, they require minimal upkeep, which reduces downtime and contributes to their cost-effectiveness. Security and Comfort: Trendy stationary hydraulic breakers come with options designed to enhance operator safety and consolation. Reduced vibration ranges decrease the danger of long-term well being issues for operators, whereas improved management mechanisms guarantee precise operation. Price-Effectiveness: Whereas the preliminary investment could also be higher than for another instruments, the longevity, low upkeep needs, and excessive effectivity of stationary hydraulic breakers make them a cost-effective choice in the long run. Environmentally Pleasant: Many models are designed to be environmentally friendly, with options similar to noise and dust control programs that decrease their impression on the encircling environment. Cell hydraulic breakers are a game-changer in the construction and demolition industries.

- 이전글Are You Making These Cbd Suisse Errors? 24.10.18

- 다음글A Glimpse In The Secrets Of ADD Natural Treatment 24.10.18

댓글목록

등록된 댓글이 없습니다.